Mining and Resources Engineering and Fabrications

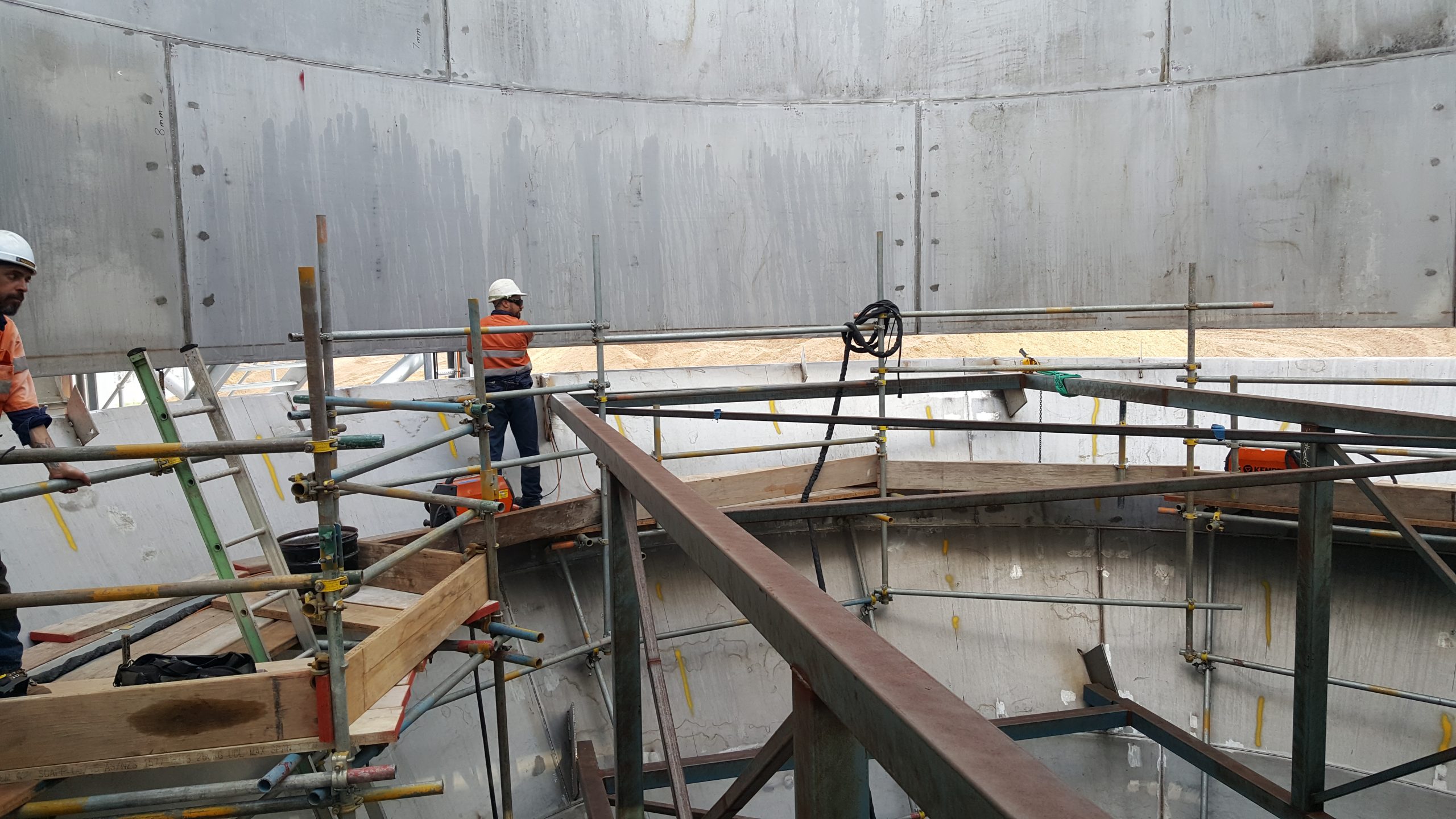

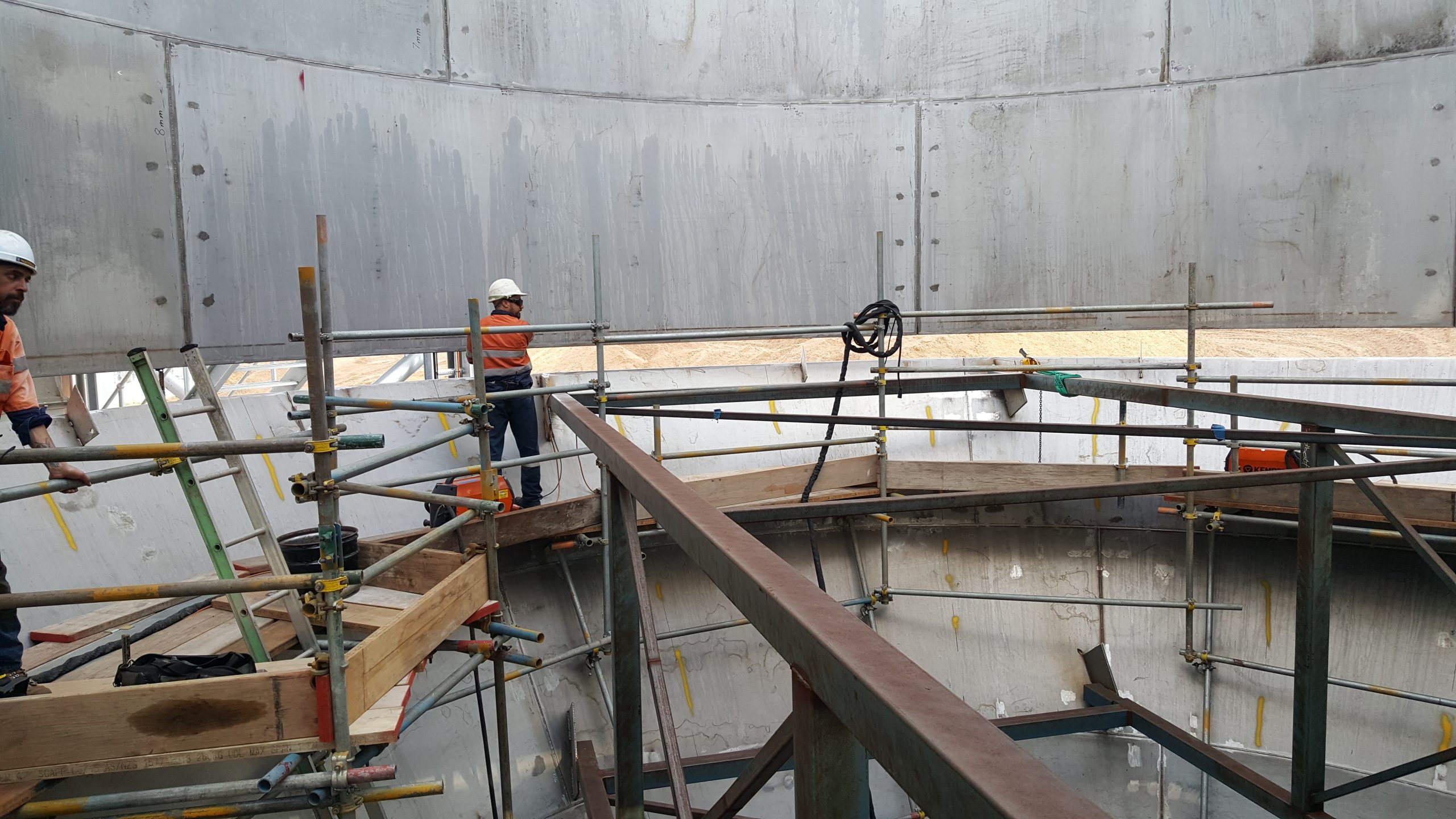

Partnering with some of the biggest names in the Mining and Resources sector has given the Shadbolt Group the opportunity to demonstrate our engineering, fabrication and installation know-how and expertise. Having a diverse range of skills has enabled us to build on our experience and our reputation for going that extra mile for the best possible outcome.

Our dedication to quality follows from initial planning, each procedure, the task at hand and delivering the final results. Our focus is always on what is best for the client and their needs with the Shadbolt Group’s trademark of reliability in all that we do.

Whether it’s specialised or custom-built equipment such as parts required for the process of separating sand and mineral from gas as it is being extracted, you can always rely on the quality work of Shadbolt Group. We only ever provide the very best to all our

clients and partners. Fabrication and installation of equipment as well as mechanical and structural experience in those areas requires a specific expertise. Mechanical works relating to motors, gearboxes, slewing gears, conveyors and bearing housing rebuilds

are all part of ‘a day in the life’ of the people at Shadbolt Group.

We work with the following materials – Mild Steel, Stainless Steels (304, 316, Duplex), Aluminium, Copper-Nickel.

We also apply various coating systems to AS2312 and AS4680 to comply with corrosive and harsh environments

Our fabrication skills and engineering services across the Mining and Resources sector include:

- Weld procedure compliance

- Welding to applicable codes such as ASME IX, AS3992, AWS D1.1 & AS1554

- Machine Building and refurbishments – including the machining and fabrication of components to tight tolerances

- Quality assurance

- Engineering excellence

- Quality documentation submission – including MDRs and Full Traceability

- Installation and site management services

- Confined Space works and Working at Heights

- Project Management – apply PMBOK® philosophies