Water and Wastewater Custom Fabrications

Water is one of the most precious resources on the planet. The best use of water and wastewater is integral to the well-being of the wider community and in a broader sense the entire planet. Shadbolt Group specialises in fabrication and installation of water treatment plants, having completed in a wide range of advanced and conventional treatment plant process technologies. We are skilled in all facets of water and wastewater construction including ongoing maintenance services, delivering infrastructure solutions to meet large-scale urban and regional development.

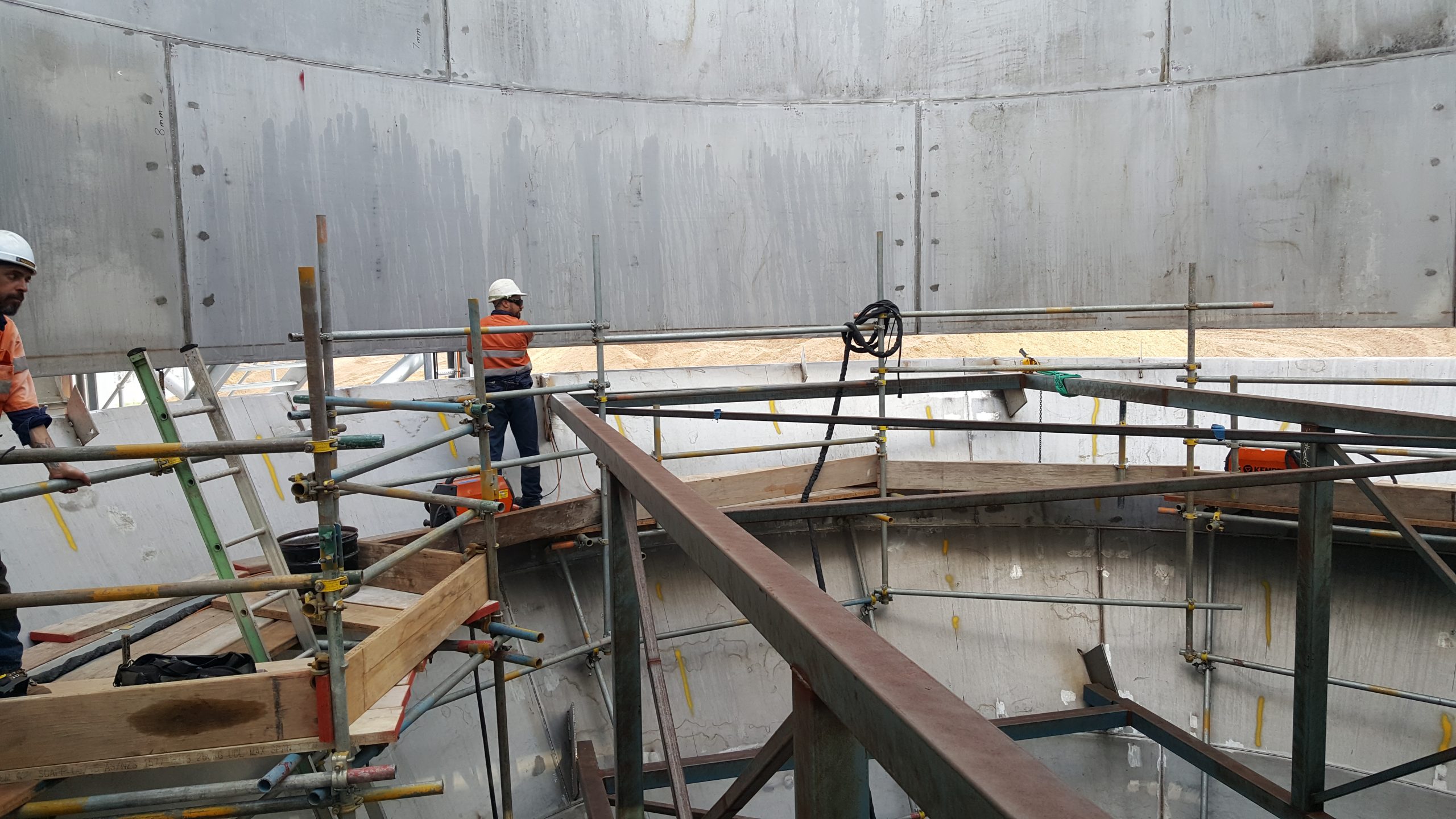

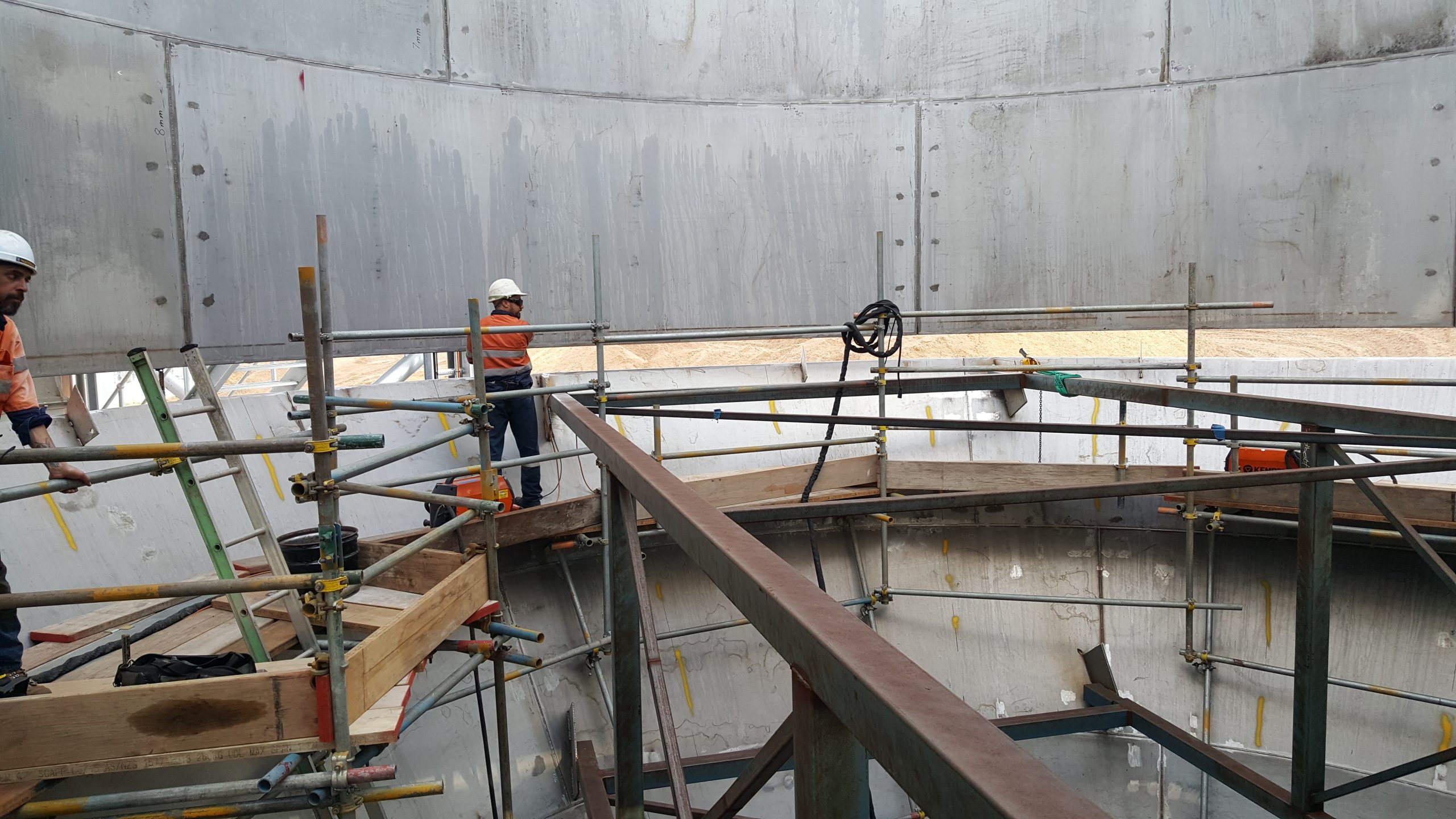

Shadbolt Group provides project management, engineering, fabrication and construction services, delivering maintenance, shutdown and capital works projects to the water & wastewater sectors. Our total solutions range from engineering design, fabrication, project management, construction, and commissioning to ongoing maintenance. This includes SMP (structural mechanical and piping) capability and cost-efficient, fixed-price solutions that have earned us repeat business from many of the state’s leading resource and industrial enterprises.

That’s why when it comes to water and wastewater custom fabrications, you need a team of true professionals to get the results you are after.

The team at Shadbolt Group are the professionals you can rely on. Our aim is always on providing the best of our wealth of skills and knowledge for each and every client. It’s our focus on getting every detail right that allows us to produce the highest standards of quality. We have an unmatched reliability when it comes to engineering excellence across a whole range of water and wastewater custom fabrications.

Delivering on all we promise is one of the trademarks of our work. All our clients and partners know that when you deal with Shadbolt Group, you’re getting a trusted team who combine expertise, experience and a ‘Can Do’ attitude.

Our skills and services across the Water and Wastewater sector include:

- Pipework (carbon, stainless and PVC) (AS 4041, ASME B31.3, ASTM D2855)

- Welding to applicable codes such as AS3992, AS1554, ASTM D2855

- Process equipment installation and fit up including – screw presses, filtration systems (sand, reverse osmosis, etc), conveyors, blowers, pumps, valves, instrumentation, etc

- Pump and Valve Rebuilds

- Running Equipment plant maintenance

- Structural steel

- Platforms and stairways

- Tank fabrications (API 620)

- Plant breakdown repairs

- In-house pressure testing services

- Installation and site management services

- Confined Space works and Working at Heights

- Project Management – apply PMBOK® philosophies