Structural Steel Fabrication in Hallam

Shadbolt Group is your premier choice for engineering solutions throughout Australia. Our expertise includes bespoke metal fabrication, steel pipe spooling, comprehensive pipework systems, and shipbuilding and sustainment, among others.

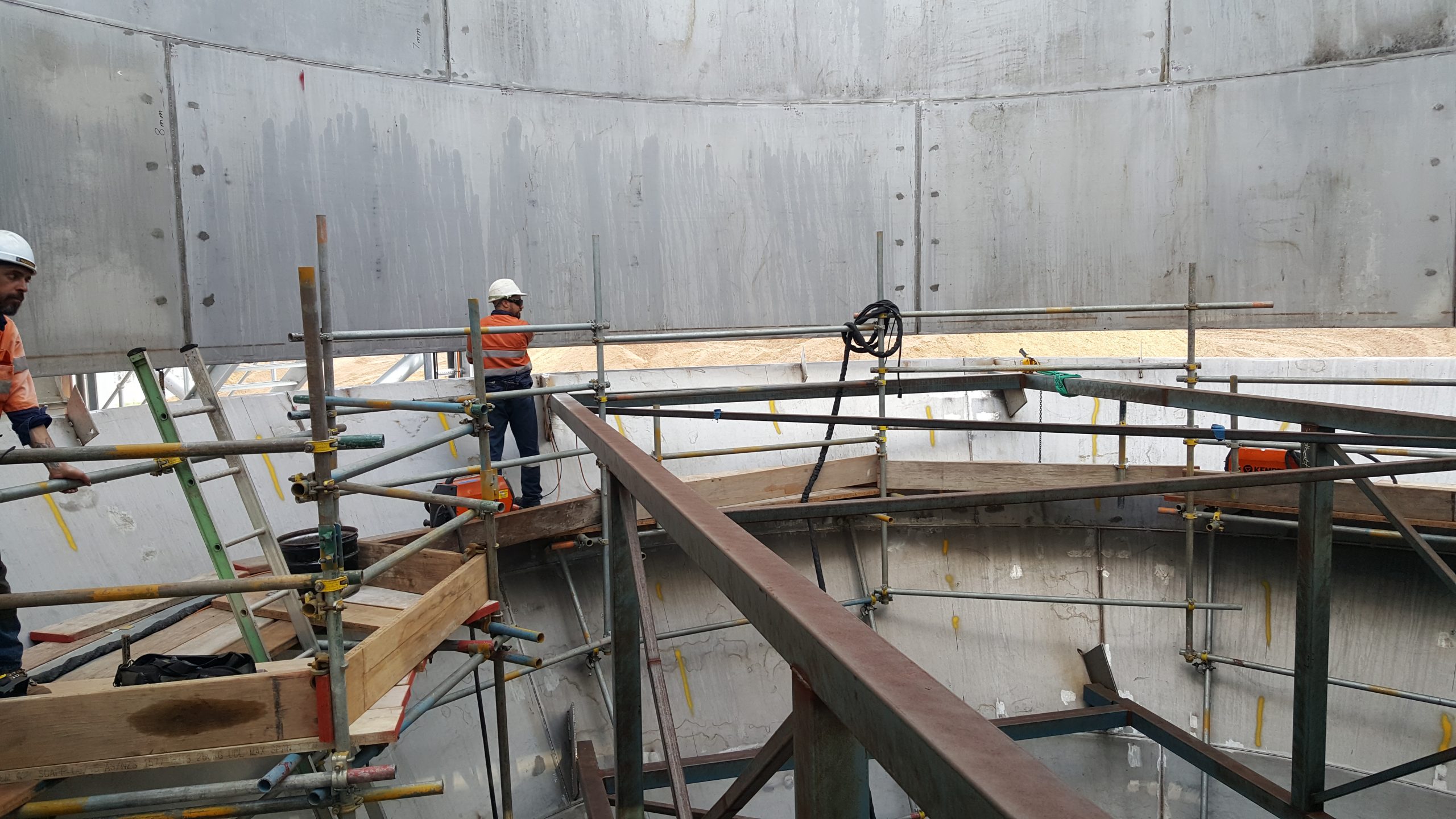

Equipped with state-of-the-art facilities in our workshop, including overhead cranes, ample vehicle access, and an extensive array of welding equipment, we can cater to your custom machining and fabrication needs including structural steel fabrication.

Our commitment extends beyond delivering quality metal fabrication and installation. We also offer invaluable industry expertise and go above and beyond to fulfil your unique requirements. Trust us for superior quality structural steel fabrication in Hallam, delivered promptly and within your budget.

At Shadbolt Group, maintaining traceability is fundamental to our operations. We recognize the significance of quality and prioritize excellence and dependability.

Our expertise surpasses welding. For each bespoke steel fabrication project, we guarantee traceability by furnishing duplicates of vital documents. These encompass the Inspection & Test Plan, Safe Work Method Statement, Welding Procedure Specification, Welder Qualification Record, and Welding Record Sheet.

Our trade capability is second to none, covering the areas of:

- Defence

- Energy, Oil & Gas

- Feed & Biofuel

- Food & Beverage and Pharmaceuticals

- Mining & Resources

- Automotive

- Pulp & Paper

- Water & Wastewater

- Maritime

- Furnaces & Combustion

We also offer other specialised services, including the following:

- In-house welding supervisors and inspectors

- Welding pipework of dissimilar metals

- Repair & Refurbishment of existing installations

- Fast Response to clients’ urgent requirements

- Fast-track project delivery as required

- Plant Shutdowns & Turnarounds

- Turnkey Projects

Why Choose Shadbolt for Structural Steel Fabrication in Hallam

Initially founded as Shadbolt Engineering in Melbourne, our expansion has resulted in five locations nationwide, including a facility in Hallam. Our highly skilled team consists of more than 200 operations staff, engineers, electricians, and welders certified in specialised and bespoke metal fabrication.

Managing projects with stringent quality assurance demands is a routine facet of our operations. Our steadfast dedication to quality is demonstrated by the multitude of accreditations and affiliations garnered over the years.

- AS/NZS ISO 9001:2016 Quality Management Systems (Manufacture and Installation of Steel Fabrication structures, equipment, and components)

- Lloyd’s Register Rules for Weld Procedures

- Weld Australia – Member Number 500682

- AS/NZS ISO 3834 Part 2 – Weld Quality Systems

- DNV Welding Workshop Approval (WWA) Certificate (Approved for Hull Structures, Hull Equipment and Machinery Components)

- Defence Industry Security Program (DISP) Membership

- Australian Industry & Defence Network (AIDN) Membership

- Hallam Alliance Membership

At Shadbolt, our steadfast dedication to quality is apparent as we meticulously enforce control protocols and adhere to industry standards throughout the fabrication process. Our primary goal is to ensure safety, durability, and compliance with relevant regulations, instilling our clients with a profound sense of confidence and peace of mind.

Choose Shadbolt as your primary ally for structural steel fabrication, where our commitment is focused on establishing fresh industry standards. Contact us today to initiate conversations regarding personalised metal fabrication and delve into the variety of supplementary services we provide.