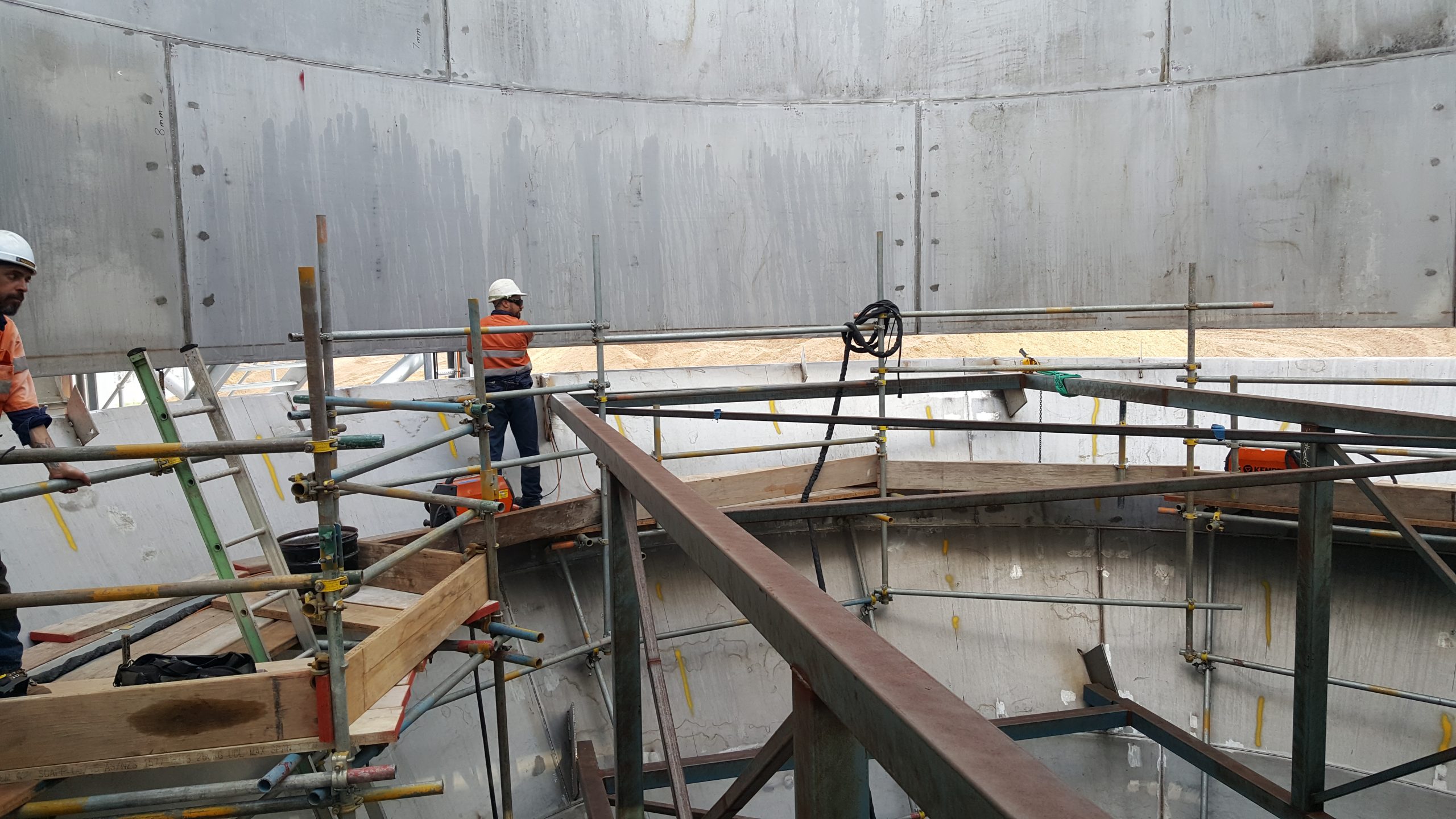

Stainless Steel Pipework Fabrication

For stainless steel pipework fabrication, Shadbolt Group stands as a premier engineering service provider. Our expertise extends to all facets of pressure piping, ensuring meticulous compliance with specific codes. When dealing with stainless steel, we understand the unique properties of this material, allowing us to tailor our fabrication processes to meet the highest standards of durability and corrosion resistance.

Understanding that our customers seek more than a mere pipework supplier, we recognize the importance of industry knowledge. Our commitment goes beyond the ordinary, as we willingly go the extra mile to fulfil their requirements. Clients trust us explicitly to provide top-quality stainless steel pipework fabrication and installation, ensuring timely delivery and adherence to budget constraints.

In our pursuit of excellence, we acknowledge that the job isn’t complete solely because the stainless steel pipe is welded.

For each pipe welding project, we have the capability to furnish duplicates of the Inspection & Test Plan, Safe Work Method Statement, Welding Procedure Specification, Welder Qualification Record, and Welding Record Sheet.

Our pipework fabrication capabilities include:

- Shop drawing

- Shop spooling

- Skid units, pipe racks/pre-assembled units & site installation

- Stainless steel, carbon steel, copper, nickel, and aluminium

- Piping designed for high-pressure and/or corrosive applications

- Pipe sizes 15NB to 1500NB

- Development of drawings from simple layouts/schematics into working fabrication/installation drawings (provide as-built drawings)

- Non-destructive testing by arrangement

- General Mechanical Engineering

- Piping & Control Systems

- Pipe Header Systems & Manifolds

- Pipe Racks/Skid Units/Pre-Assembled Units

We also offer other specialised services, including the following:

- In-house welding supervisors and inspectors

- Welding pipework of dissimilar metals

- Repair & Refurbishment of existing installations

- Fast Response to clients’ urgent requirements

- Fast-track project delivery as required

- Plant Shutdowns & Turnarounds

- Turnkey Projects

Our welding expertise includes:

- Processes – SMAW, GTAW, GMAW, STT, etc.

- Welding Specification Standards – ASME IX Boiler & Pressure Vessel Code Welding

- ASME IX & AS3992 Welding Procedures

- Welder Approval and Qualification to AS3992, AS4041, ASME IX, ASME D31.3

Our proficiency is complemented by our distinctive ‘Can Do’ approach with a dedication to accomplishing tasks accurately – within specified timelines and budget constraints. This embodies the unique differentiator that sets Shadbolt apart.