Jansz-Io Compression Floating Control Station (FCS) – Hull Super Duplex Submergible Pump Piping System Project

Shadbolt Group is a leading provider of fabrication services across various sectors, and our current involvement in Chevron’s prestigious Jansz-Io Compression Field Control Station (FCS) project exemplifies our extensive capabilities. This case study highlights Shadbolt Group’s expertise in material fabrication, stringent quality control, and adherence to international standards, making us a trusted partner by those in the energy, oil, and gas industry. Shadbolt Group’s involvement in the Jansz-Io project began in November 2023.

Project Overview:

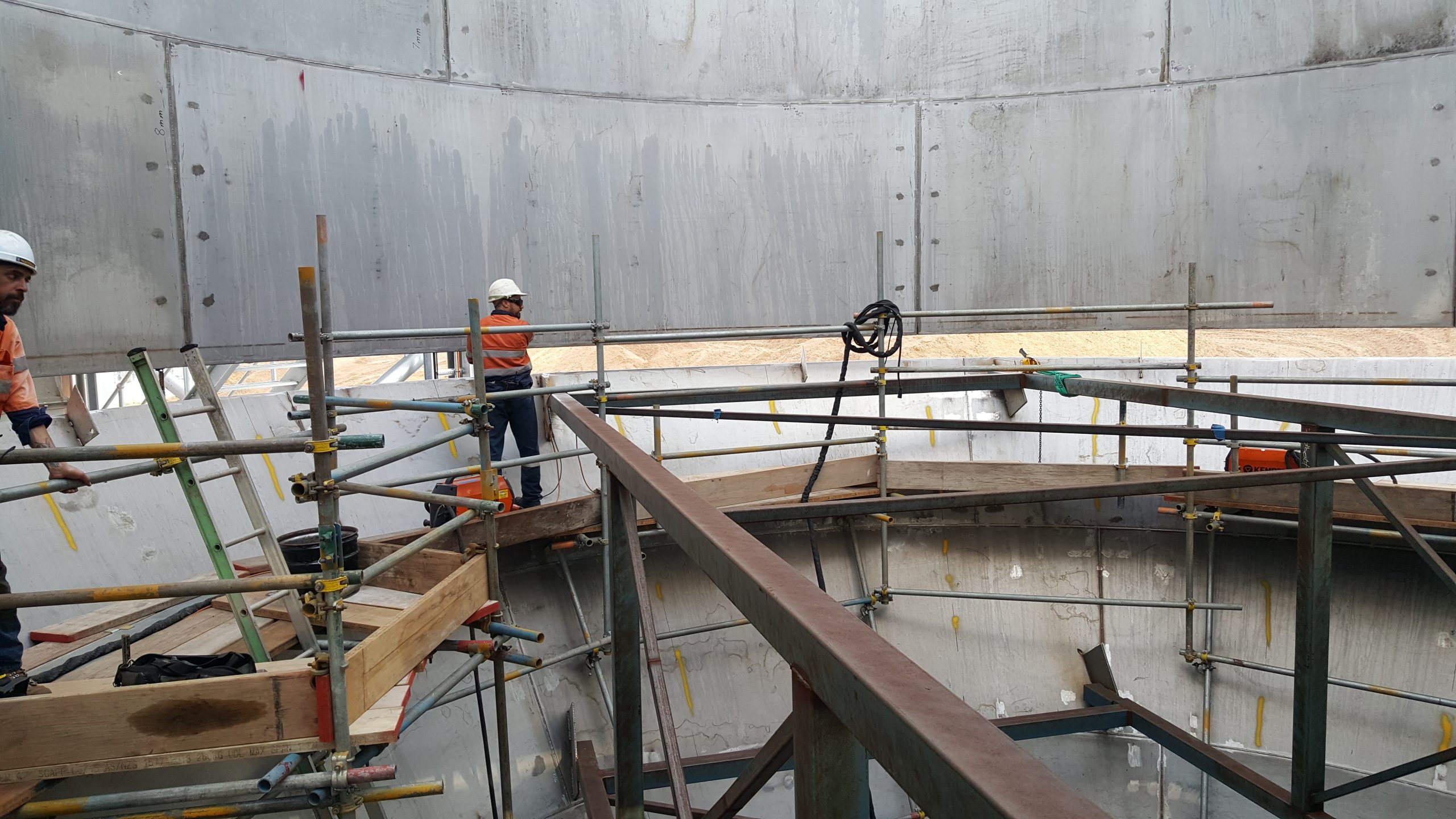

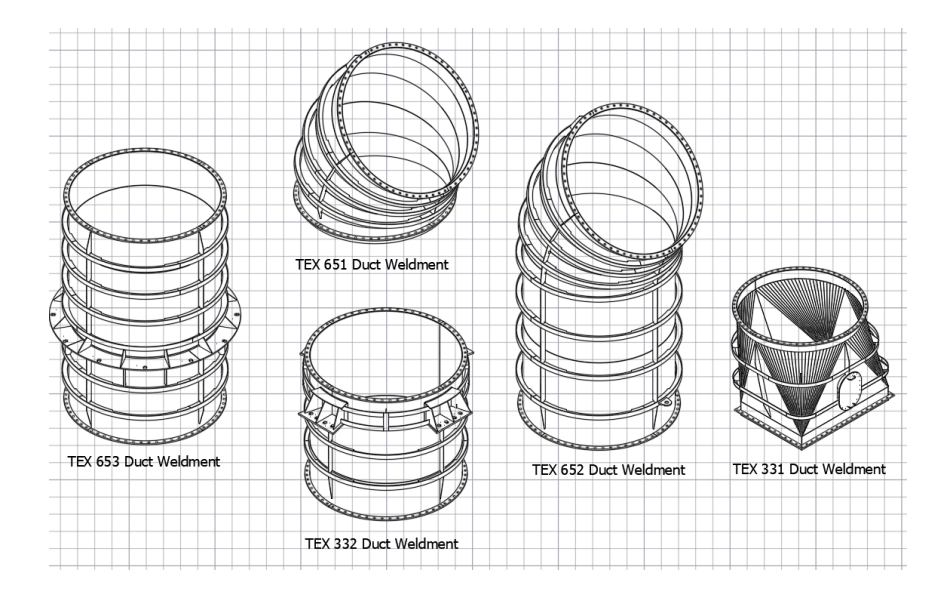

Shadbolt Group’s Pakenham workshop is proud to be contributing to the prestigious Jansz-Io Compression Field Control Station (FCS) project. Our team is responsible for fabricating the submergible pump piping system for the project’s hull. This vital component will be constructed from Super Duplex Stainless Steel (25Cr), chosen for its exceptional resistance to harsh offshore environments.

About the Jansz-Io Compression (J-IC) project:

This project leverages established subsea compression technology, ensuring continued natural gas supply to LNG and domestic gas plants on Barrow Island. Furthermore, the installation of compression and supporting infrastructure lays the groundwork for future integration of other fields within the Greater Gorgon Area.

Our work on the project includes:

- Developed and qualified welding procedures: Our team specializes in welding techniques specifically for Super Duplex Stainless Steel. These procedures meet the rigorous demands of both Chevron’s specifications (USA) and DNV-OS-C401 (DNV offshore regulations). This includes passing stringent tests like G48 Method A corrosion testing and impact testing to minus (-) 57DegC

- Third-party approvals obtained: The developed welding procedures have been approved by DNV Offshore and DSME Shipyard, South Korea, which guarantees that we adhere to international quality and safety standards

- Project completion: the field control station (FCS) for the Jansz-Io Compression project offshore Australia is expected to be completed by 3Q 2025

Our commitment to utilizing advanced materials, adhering to international standards, and maintaining a skilled workforce positions us as a reliable partner for clients across various industries

Key Achievements in Fabricating the Submergible Pump Piping System:

- Fabricating Over 200 Spools: Shadbolt Group is currently manufacturing over 200 spools of Super Duplex (25Cr) piping specifically meeting project requirements

- Skilled Workforce: A team of highly skilled and experienced exotic piping welders from Shadbolt Group were chosen to ensure success

- Certified Quality Management: We have a system in place called the ISO 3834-2 Welding Quality Management System. This helps our Quality, Production, and Project Management teams make sure everything is done exactly right, meeting the high standards set by our client, Chevron

- Meeting Client Expectations: Throughout the project, Shadbolt Group aims to maintain all required standards, with the goal of exceeding Chevron’s stringent quality requirements

No matter the project, we are dedicated to utilizing advanced materials while adhering to international standards, and maintaining a highly skilled workforce which positions us as a trusted and reliable partner for clients across various industries. We always ensure successful project completion and plan to exceed expectations at every step of the way.

This project not only highlights our technical expertise and dedication to quality but also showcases our unwavering commitment to exceeding client expectations and forging long-lasting partnerships within the energy sector. The Jansz-Io project serves as a testament to our unwavering dedication to excellence.