Custom Metal Fabrication in Hallam

Renowned as a premier provider of engineering solutions in Australia, Shadbolt Group prides itself on our specialisation in custom metal fabrication, steel pipe spooling, and comprehensive pipework systems.

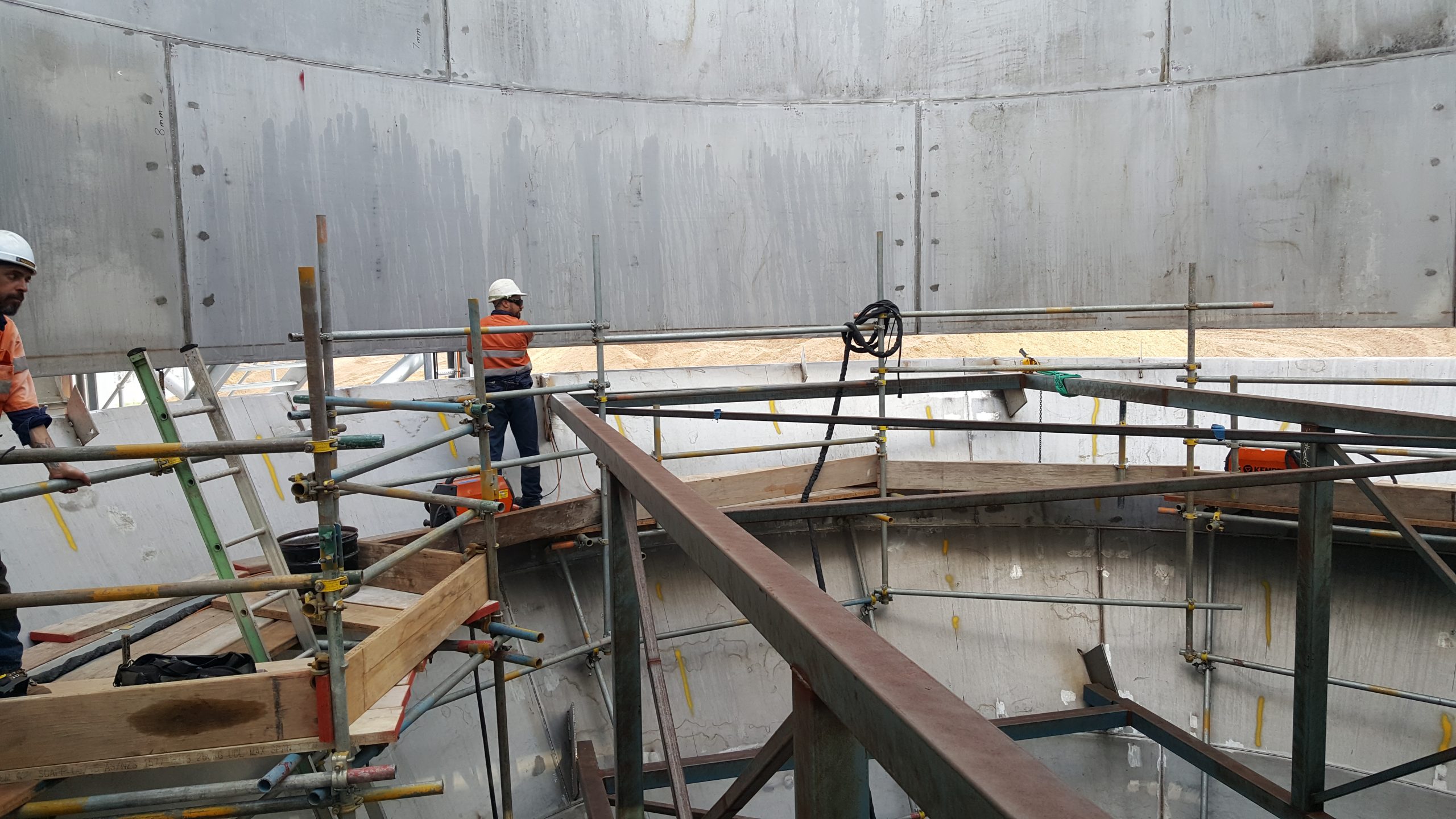

Located in Hallam, VIC, our cutting-edge workshop is fully equipped with advanced tools, including overhead cranes, extensive vehicle access, and a diverse array of welding equipment. These resources significantly bolster our capabilities, so we can consistently meet and surpass your expectations.

With an understanding that your requirements surpass those of a standard pipework provider, Shadbolt Group values the significance of collaborating with a trusted partner knowledgeable in all aspects of pressure piping, particularly custom metal fabrication, to ensure alignment with specific codes.

Delivering exceptional custom metal fabrication and installation is just the beginning for us; our commitment involves providing valuable industry insights and exceeding expectations to meet your specific requirements. Clients and partners trust our team to deliver superior quality promptly and within budget constraints. Depend on our team for unparalleled custom metal fabrication in Hallam.

Shadbolt Group places a strong emphasis on maintaining traceability in all our operations. We deeply understand the importance of quality and prioritise excellence and reliability.

Our dedication to you extends beyond welding completion. For every project in Hallam, we provide duplicates of critical documents, including the Inspection & Test Plan, Safe Work Method Statement, Welding Procedure Specification, Welder Qualification Record, and Welding Record Sheet.

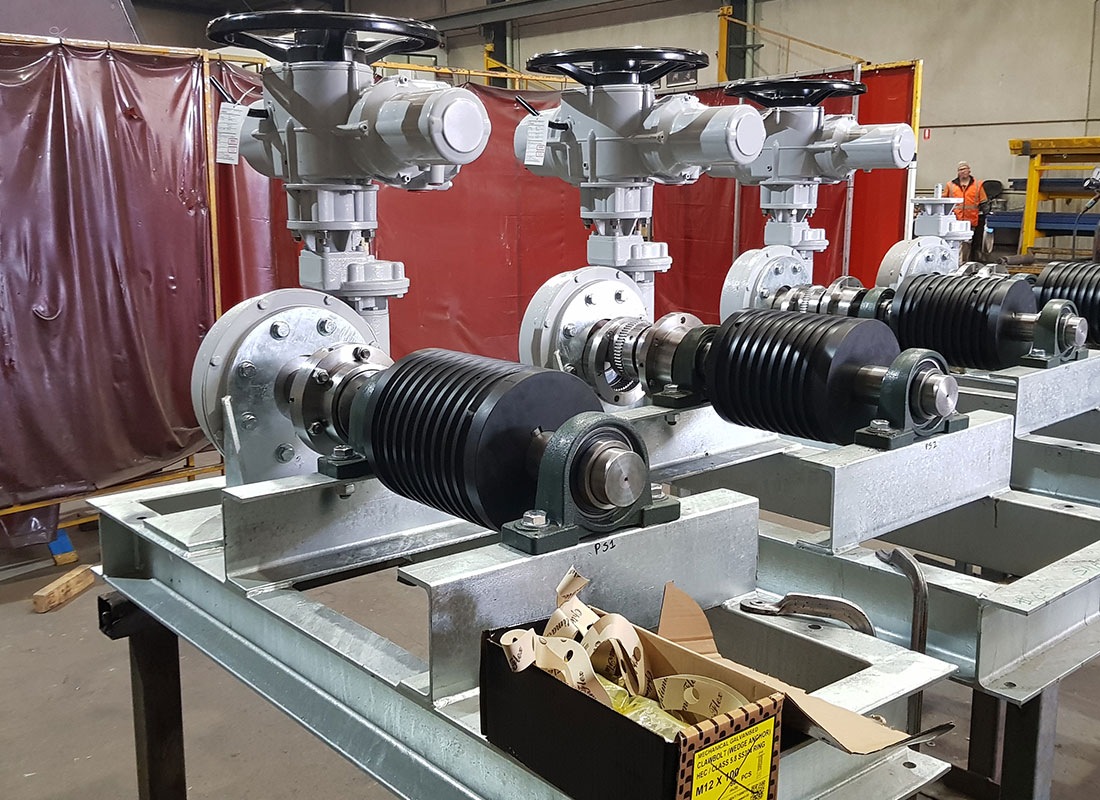

Our pipework fabrication capabilities include:

- Shop drawing

- Shop spooling

- Skid units, pipe racks/pre-assembled units & site installation

- Stainless steel, carbon steel, copper, nickel, and aluminium

- Piping designed for high-pressure and/or corrosive applications

- Pipe sizes 15NB to 1500NB

- Development of drawings from simple layouts/schematics into working fabrication/installation drawings (provide as-built drawings)

- Non-destructive testing by arrangement

- General Mechanical Engineering

- Piping & Control Systems

- Pipe Header Systems & Manifolds

- Pipe Racks/Skid Units/Pre-Assembled Units

We also offer other specialised services, including the following:

- In-house welding supervisors and inspectors

- Welding pipework of dissimilar metals

- Repair & Refurbishment of existing installations

- Fast Response to clients’ urgent requirements

- Fast-track project delivery as required

- Plant Shutdowns & Turnarounds

- Turnkey Projects

Our welding expertise includes:

- Processes – SMAW, GTAW, GMAW, STT, etc.

- Welding Specification Standards – ASME IX Boiler & Pressure Vessel Code Welding

- ASME IX & AS3992 Welding Procedures

- Welder Approval and Qualification to AS3992, AS4041, ASME IX, ASME D31.3

Why Choose Shadbolt for Custom Metal Fabrication in Hallam

Shadbolt Group boasts a distinguished legacy spanning more than four decades, maintaining a prominent presence in custom metal fabrication while delivering superior engineering, support, and maintenance services across various sectors, including defence, mining, transportation, and energy.

Arising from Shadbolt Engineering in Melbourne, our expansion has led us to establish five nationwide locations, including a specialised workshop in Banksmeadow. Our esteemed workforce, comprising over 200 renowned engineers, maritime electricians, and welders, is acknowledged as certified experts in welding and custom metal fabrication.

Engaging in projects with intricate quality assurance requirements is an integral aspect of our operations. Our steadfast dedication to quality is evident through numerous accreditations and affiliations accumulated over the years.

- AS/NZS ISO 9001:2016 Quality Management Systems (Manufacture and Installation of Steel Fabrication structures, equipment, and components)

- Lloyd’s Register Rules for Weld Procedures

- Weld Australia – Member Number 500682

- AS/NZS ISO 3834 Part 2 – Weld Quality Systems

- DNV Welding Workshop Approval (WWA) Certificate (Approved for Hull Structures, Hull Equipment and Machinery Components)

- Defence Industry Security Program (DISP) Membership

- Australian Industry & Defence Network (AIDN) Membership

- Henderson Alliance Membership

Shadbolt’s commitment to quality is evident as we rigorously enforce control protocols and adhere to industry standards during the fabrication process. Our primary objective is to guarantee safety, durability, and compliance with relevant regulations, offering our clients a deep sense of confidence and tranquillity.

Choose Shadbolt as your trusted partner for custom metal fabrication in Hallam, where we spearhead the establishment of new industry standards. Get in touch with us today for custom metal fabrication and inquire about the additional services we offer.